|

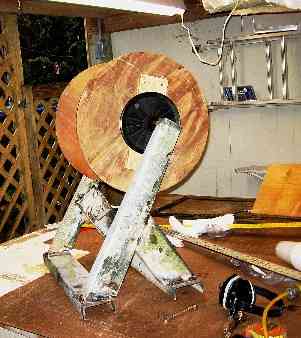

Fixturing and method are of prime concern, had to do some thinking about how to build the boost in both effecient thrust

and more effective re-generation from the 3 blade 14/11 prop being used...

Being round (the Nozzle) and configured like an ole barrel with a specific airfoil on the inside diameter and outside

it is necessary to have a rotary device, if you happen to have a 20 inch lathe, you have no problem, I don't, so had to make

from scrap parts laying around Doc John's dungeon.....good place to scrounge....thanks Doc

Building a drum that will be filled with 8 lb. foam and then shaped to form the inside diameter of the nozzle.

|